EPA Standards Explained: Wood Burning Efficiency Through the Ages

How Today’s Wood Stoves Compare to Old units

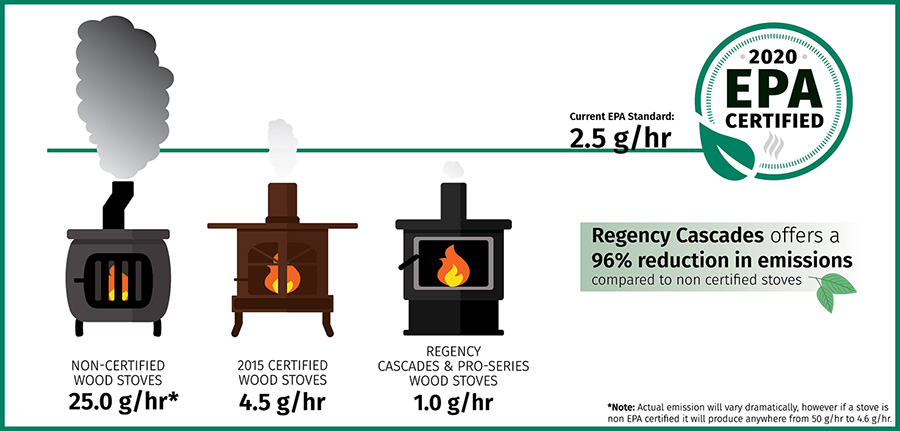

Current wood burning stoves are a safe, efficient, and clean way to heat your home – producing up to or less than 2.5 grams per hour of particulate matter and dramatically reducing the release of PM 2.5 – the fine particulate matter most targeted by anti-wood legislation/activists.

Wood is a great source of heat for off-grid and unstable-grid based homes – keeping people warm, safe, and comfortable during power outages, storms, or unforeseen weather events. The best way to reduce emissions from wood burning stoves and reduce their impact on air quality is to replace old wood stoves with today’s high-efficiency EPA-certified wood stoves. According to a report released by the EPA on reducing residential wood smoke “Changing out one old, dirty, [uncertified] wood stove is equivalent to the PM 2.5 pollution reduction of taking five old diesel buses off the road.”

The EPA in the United States began regulating wood stove emissions in 1988 and has since made several changes to the standards to reduce emissions, decrease PM 2.5, increase efficiency, and improve overall stove performance. The resulting changes have forced many manufacturers to innovate their wood stove lineup or leave the production of wood burning units completely – the result is innovative burn technologies and hyper-efficient units.

| Years of Regulation |

Unit Type |

Emissions Standards |

| Pre-1988 |

All |

No emissions standards |

| 1988 - 2014 |

Non-Catalytic |

< 7.5 g/hr |

| 1988 – 2014 |

Catalytic |

< 4.5 g/hr |

| 2015-2019 |

All |

< 4.5 g/hr |

| 2020 – Today |

All |

< 2.5 g/hr |

Uncertified Wood Stoves: >50 g/hr in Emissions

Uncertified wood burning wood stoves or open fireplaces produce more than 50 grams/hour of particulate matter. Depending on the unit, wood, moisture content etc. they can produce as much as 100 grams/hour of particulate matter.

1988-2014 <7.5 g/hr in Emissions

The EPA first regulated emissions standards in 1988 stating that all non-catalytic wood stoves must produce fewer than 7.5 grams/hour in particulate emissions. For all Catalytic units the standard was 4.5 g/hr. The result of this initial regulation was the introduction of secondary burn and catalytic wood stoves as manufacturers scrambled to decrease their emissions. The result of these last-minute additions in catalyst and secondary burn air tubes were units that met standards but were prone to break, needed replacement parts regularly, and just generally didn’t perform to the level they were expected to. At this point many manufacturers stopped producing wood burning units as they had trouble meeting the current standards. In addition to the EPA standard, the state of Washington had a standard of 4.5 g/hr for all units – so this was a threshold that many manufacturers tried to achieve so they could sell throughout the United States.

2015-2019 <4.5 g/hr in Emissions

In 2015 the EPA enacted Step 1 (of 2) NSPS standards to further decrease emissions – stating that all units both Catalytic and Non-Catalytic had to produce fewer than 4.5 g/hr. These are the first of what are considered modern wood stoves and are extremely efficient. Manufacturers used what they learned in previous iterations of regulations and were able to create well-designed, durable, and high-performance catalytic and non-catalytic units that limited emissions, increased burntimes, and provided exceptional performance.

2020 to Today <2.5 g/hr in Emissions

In 2020 the second step of NSPS standard went into effect mandating that all wood burning appliances cannot produce more than 2.5 grams/hour of particulate matter. This is up to a 96% reduction in pre-certification levels and this latest standard has driven even more manufacturers out of the wood burning category – leaving only those who are able to create clean burning models. Many current models use two-stage or three-stage combustion technology to re-burn particulate matter, increase efficiency and maximize burntimes.

How Wood Stove Testing Works

Manufacturers of wood stoves are required to get their products tested and approved by the EPA (or other regulatory bodies) before they can be sold in the US or Canada. Testing is completed by an EPA accredited lab or certification body and an extensive and precise report must be sent to the EPA for approval. Once received, the EPA will review all data from the reports burn tests and determine if a unit is approved or if further testing is required. When testing there are two testing methods using different types of wood – Crib Wood and Cord Wood. See Regency EPA data & reports

Crib Wood Testing Method

Crib wood is diminesional lumber - pieces of douglas fir that have been stapled together to create a grid. Crib wood is used to create a more standardized test that can be easily replicated in a laboratory environment. The 2020 EPA standard for Crib Wood testing is actually slightly lower to help account for the fact that this is a standardized wood and testing method and therefore does not exactly match real-world burns – 2.0 g/hr..

Cord Wood Testing Method

Cord wood uses split firewood and closely resembles real-world burning practices. Testing with Cord wood will provide a closer picture of a stoves emissions and efficiency but produces some variations in the laboratory environment. Regency tests all of it’s wood stoves & inserts using the Cord wood method to produce accurate and as close to real-world results as possible. Currently the EPA is reviewing its testing protocols & standards to help align the real-world results with the laboratory results and increase consumer confidence in testing, certification and the 2020 NSPS standard.

Proper Wood Burning Practices

The wood stove is only as efficient as the person operating the unit. It is imperative that proper wood burning practices are followed. The single largest mistake for the average homeowner is using wood that is too wet. Wet wood is equivalent to adding water to the fireplace, cooling it down, decreasing efficiency, and increasing the smoke/emissions output. For example, using green/wet wood (~50% moisture) for every 10 pounds of fuel that is burnt, that would equate to an additional 3 pounds of water or the equivalent of throwing 2.5 cups (0.5L) of water on the fire compared to seasoned wood with a moisture content less than 20%. Learn more about wood burning best practices here

Note: As regulations continue to change the startup procedure for wood stoves and inserts is also changing. Clean burning EPA wood stoves and inserts require more time during each stage of the startup process.

You May Also Like…